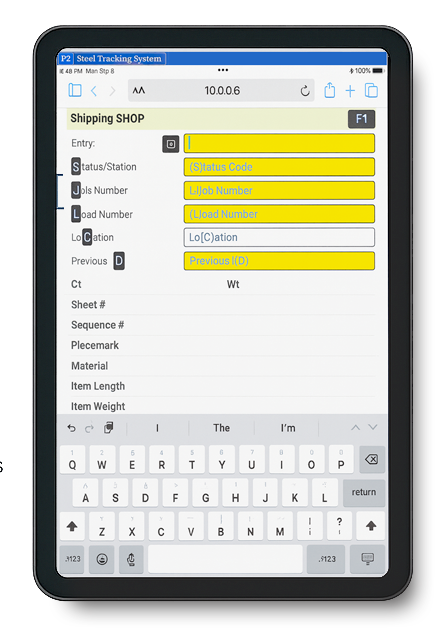

STSX 2.0—Tracking Without Limits

Real-time steel tracking from any device. Total visibility, zero delays.

- Live production status on every piece of steel

- Mobile access—phone,tablets, scanners

- Barcode accuracy with near-zero errors

- Instant answers for customers & project partners

Label printing powered by BarTender®

Why STSX?

Real-time visibility on any device—Apple, Android, Windows

Barcode tracking from receiving to shipping. Anytime. Anywhere.

Cut shipping errors and improve on-time delivery

Mobilize your workforce—scan right from the shop floor

How it Works

Receiving & Barcoding Tagging

Shop Floor Tracking & Tablet Mobility

Assembly & OC

Shipping & Load-out

1 – Capture Work Instantly

Workers scan pieces and assemblies as soon as production begins.

Every scan delivers clean, structured data straight into the system.

-

Barcode or QR capture

-

Automatic time and location stamping

-

Virtually zero manual data entry

-

Immediate model/database updates

The day starts with certainty, not guesswork.

2. Track Production as It Happens

STSX follows each item from operation to operation, providing live data from your shop floor.

-

Real-time progress tracking

-

Feedback on completed operations

-

Visibility into bottlenecks, idle stations, and priority work

-

Realtime alerts if processing items ON HOLD

What’s complete, what’s in motion, and what needs attention all rise to the surface.

3. Manage Inventory & Loads

Completed assemblies flow seamlessly into staging and shipping.

-

Track assembly completion and readiness

-

Build bundles and loads with confidence

-

See what’s staged, what’s shipping, and what’s field-ready

Every piece finds its place — and the right truck — without the scramble.

4. Report, Review, Predict

STSX closes the loop with clean reporting and full production traceability.

-

Exportable progress summaries

-

Operation-by-operation history

-

Insight into throughput and labor hours spent

-

Patterns that inform planning and forecasting

The shop tells its own story, and the data points the way forward.

Features

Unlike traditional shop-floor systems that require a PC, STSX is built for mobility. Your team can finally move freely—with live, accurate data, instead of going back to the office to look things up.